In the dynamic world of custom product decoration, choosing the right printing method is crucial for quality, efficiency, and cost-effectiveness. While traditional techniques like pad printing and screen printing have their place, UV digital printing has emerged as a revolutionary technology. But how does it truly compare to older methods? Let’s delve into the distinct advantages of UV printing and why it’s becoming the go-to solution for modern businesses.

What is UV Digital Printing?

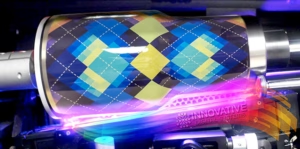

At its core, UV digital printing is an advanced process that utilizes ultraviolet (UV) light to instantly cure (dry) ink as it’s applied to a surface. Unlike conventional inks that rely on absorption or evaporation for drying, UV inks contain specialized photoinitiators. These react immediately when exposed to concentrated UV light, resulting in a durable, vibrant, and instantly dry print. This innovative curing process makes UV digital printing incredibly efficient and versatile.

Understanding Traditional Printing: Screen and Pad Printing

To fully appreciate UV digital printing, let’s briefly examine its predecessors:

- Screen Printing: This classic method involves forcing ink through a mesh screen onto a substrate. Each color requires a separate screen, making it efficient for large volumes of simple, single-color designs. However, for complex, multi-color images or smaller print runs, it can be labor-intensive and less cost-effective.

- Pad Printing: Ideal for printing on irregularly shaped or curved surfaces, pad printing uses a silicone pad to transfer an image from an etched plate to the object. While effective for challenging shapes, similar to screen printing, multi-color jobs can be time-consuming, and design complexity might be limited.

Why UV Digital Printing Leads the Way: Key Advantages

UV digital printing offers significant advantages that truly set it apart:

- Unparalleled Material Versatility: Traditional methods often struggle with non-porous or heat-sensitive materials. UV printing, however, adheres beautifully to an incredible range of substrates, including glass, metal, wood, plastics, ceramics, acrylic, and a vast array of promotional products like coolers and drinkware. This opens up immense possibilities for custom product decoration.

- Instant Curing & Accelerated Production: The immediate drying of UV inks under UV light is a game-changer. This eliminates drying times, leading to faster production cycles, quicker project turnarounds, and zero risk of smudging. Products are ready for packaging as soon as they’re printed, boosting efficiency.

- Vibrant Colors & High-Resolution Detail: Since UV inks cure directly on the surface without being absorbed, they produce exceptionally vibrant colors and crisp, high-resolution images. You’ll notice superior clarity in fine details, gradients, and photographic reproductions compared to what’s often achievable with traditional methods.

- Exceptional Print Durability: Once cured, UV prints are remarkably robust. They offer strong resistance to scratches, fading, moisture, and chemicals, making them ideal for products subjected to daily wear and tear or harsh environmental conditions. This durability ensures your custom designs maintain their integrity over time.

- No Minimum Order Quantities (MOQs): High setup costs often mean traditional printing methods come with restrictive MOQs. Digital UV printing eliminates these barriers, enabling cost-effective short runs, personalized one-off items, and efficient prototyping. This is a huge win for small businesses, new product development, and unique personalized gifts.

- Environmentally Friendly Aspects: UV inks are generally considered a more eco-conscious choice. They produce zero VOCs (Volatile Organic Compounds) during the curing process, leading to fewer harmful emissions compared to many solvent-based inks.

Is UV Printing the Right Solution for Your Project?

If you seek vibrant, durable, and versatile custom printing on virtually any material, UV digital printing is undoubtedly an excellent choice. Innovative Digital Systems (IDS) Digital offers an impressive range of machines to meet diverse business needs, whether you’re interested in:

- Rotary UV Printers for cylindrical items, including models like the REVOLUTION 360° T, TWINREV 360, QUADREV 360, the RevHDL MUG PRINTER, or the TwoBee TUBE PRINTER.

- UV Flatbed Printers for direct-to-substrate printing, such as the MUTOH Xpertjet 661UF, MUTOH Xpertjet 1462UF, MIMAKI UJF-3042 MKII E, MIMAKI UJF-6042 MKII E, MIMAKI UJF 7151 PLUS II, MIMAKI JFX 200-2513, or the PRISMA & PRISMA Z-MAX series.

- The high-speed SONICJET SP100 for single-pass printing applications.

These cutting-edge machines provide unparalleled flexibility for businesses requiring custom product decoration, from aluminum awards and plaques to complex ADA/Braille signage and unique promotional items.

Ready to transform your products with advanced UV digital printing? Don’t hesitate to reach out to our experts for more information or a personalized consultation. You can connect with us directly on our Contact Us page.