At Innovative Digital Systems, we know successful UV digital printing involves more than just the printer. Indeed, it’s about the perfect synergy between your equipment, inks, and, crucially, your substrate. Understanding UV ink adhesion dyne level is therefore paramount. Ultimately, it helps you achieve vibrant, durable prints and maximize profitability. This holds true whether you’re investing in a new UV digital printer or utilizing our expert contract decoration services.

What is Dyne Level and Why Does it Matter for UV Digital Printing?

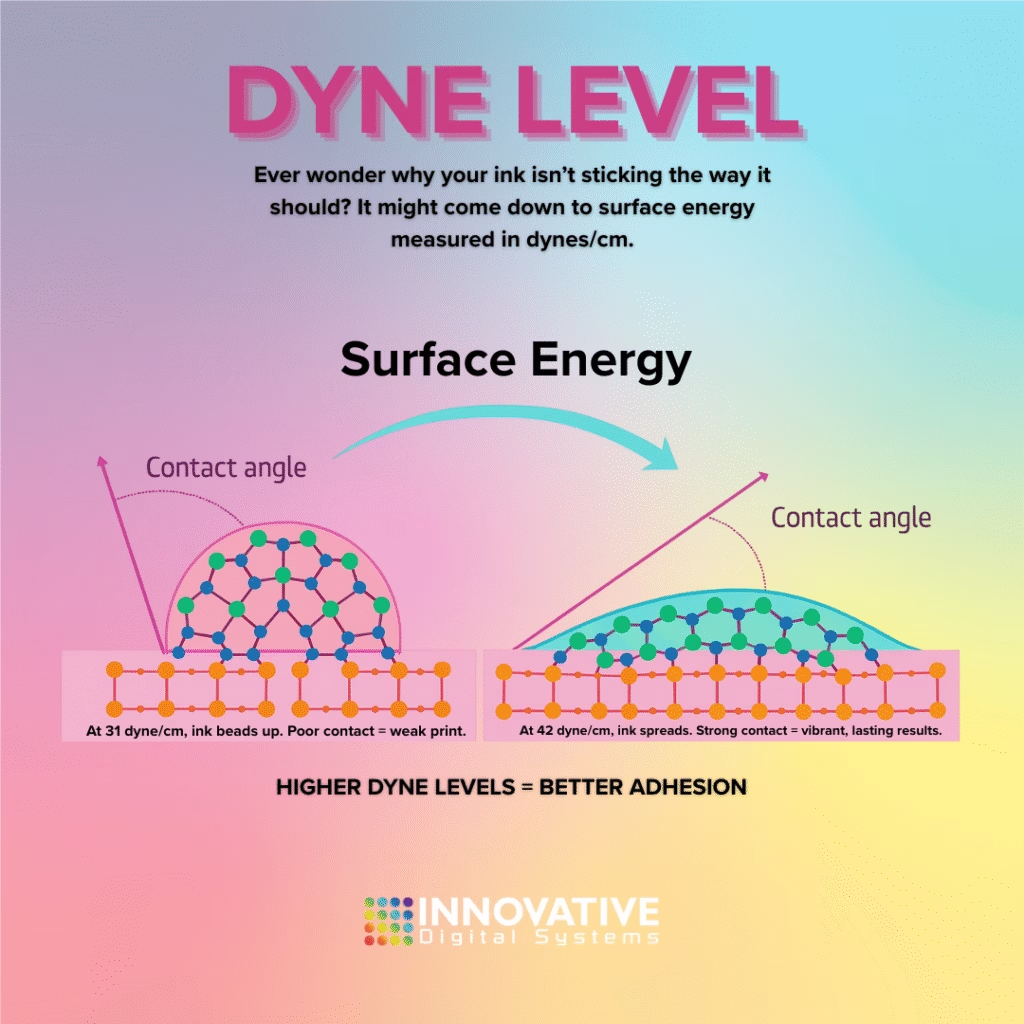

Dyne level is also known as surface energy. It measures a material’s surface tension or adhesive properties. Specifically, it’s typically expressed in dynes per centimeter (dyne/cm) or millinewtons per meter (mN/m). Furthermore, it represents the invisible force that dictates how well liquids, like your specialized UV inks, will “wet” and adhere to a solid surface.

For UV Digital Printing, higher dyne levels are your best friend. They signify better wettability and adhesion. Consequently, your UV inks will spread smoothly, bond strongly, and cure flawlessly. However, without sufficient surface energy on your substrate, you’ll inevitably face frustrating print issues:

- Poor Ink Adhesion: Inks might bead up. As a result, this leads to inconsistent coverage and a patchy appearance.

- Delamination & Peeling: Prints can easily scratch, chip, or peel off. This is especially true on flexible materials.

- Reduced Durability: Your vibrant designs won’t withstand everyday use. Thus, the quality and longevity of your products diminish.

- Banding & Curing Issues: Improper wetting can cause unsightly lines and incomplete curing. Therefore, both aesthetics and functionality are impacted.

How Innovative Digital Systems Ensures Optimal Adhesion

At Innovative Digital Systems, we are dedicated to helping you achieve unparalleled print quality. In this regard, understanding and optimizing UV ink adhesion dyne level plays a critical role in our offerings.

1. Selling High-Performance UV Digital Printers:

When you invest in a UV digital printer from Innovative Digital Systems, you gain expertise. Moreover, this expertise optimizes your entire workflow. We emphasize substrate preparation and dyne level testing as part of our comprehensive support. For instance, our curated line of UV/LED printers is designed for seamless operation with properly prepared substrates. This includes UV flatbed printers like the PRISMA Z-MAX, plus popular Mimaki models (UJF-3042 MKII E, UJF-6042 MKII E, UJF 7151 PLUS II, JFX 200-2513), and Mutoh Xpertjet models (661UF, 1462UF).

In addition, our UV rotary equipment includes the Revolution 360° T, TWINREV 360, QUADREV 360, RevHDL, and TwoBee. Furthermore, we also provide adhesion treatment systems such as the Pyrobond 4 GL and PYROTRACK: FLATBED. These systems are specifically designed to optimize adhesion for various objects, including drinkware. Ultimately, all this ensures you get the most out of your investment, whether printing on plastic, metal, or glass. We guide you on:

- Substrate Compatibility: Understand which materials suit UV printing best and their typical dyne characteristics.

- Pre-treatment Solutions: We recommend and provide solutions like Pyrosil and flame treatment systems. Indeed, these increase surface energy on challenging materials, directly impacting UV ink adhesion dyne level.

- Dyne Test Pens & Kits: We equip you with tools to perform quick, accurate dyne tests in-house. Consequently, this ensures consistent quality control for high-resolution, durable prints.

2. Expert Contract Decoration Services:

For businesses seeking top-tier contract decoration services without the upfront equipment investment, Innovative Digital Systems in Indian Trail, North Carolina, is your trusted partner. First and foremost, our team boasts over 30 years of expertise in product decoration. We understand the nuances of surface energy. Therefore, we meticulously prepare every substrate. This guarantees superior adhesion for your UV digital prints. We offer:

- Precise Dyne Level Management: We rigorously test all materials. If necessary, we treat them to achieve optimal UV ink adhesion dyne level. This maximizes ink adhesion. Consequently, your custom branding solutions will boast exceptional durability and a premium finish.

- Wide Material Versatility: Our expertise allows strong adhesion on diverse materials. This includes challenging substrates. We achieve this through in-depth knowledge of dyne levels and pre-treatment techniques. Thus, we provide industrial printing services for high-volume UV printing on plastic products, metal products, and other specialty items.

- Consistent Quality: By controlling dyne levels, we eliminate common print defects. Therefore, this ensures every piece meets the highest standards for promotional product printing and OEM printing services. Moreover, in addition to cutting-edge digital printing, we also offer pad printing, hot stamping, laser engraving, and silkscreen for comprehensive product customization.

The Bottom Line: Invest in Adhesion, Invest in Quality

Are you looking to buy a UV digital printer? Or do you need reliable contract decoration services? Either way, understanding and managing UV ink adhesion dyne level is essential. Indeed, it’s non-negotiable for achieving exceptional results.

At Innovative Digital Systems, we don’t just sell equipment or provide services. Rather, we deliver solutions. These solutions ensure your UV digital prints are visually stunning and built to last. Contact us today. Learn how we can elevate your UV digital printing capabilities. Ultimately, ensure perfect adhesion every time. We use our expertise in surface energy testing and pre-treatment for UV ink adhesion on challenging substrates. For more information on industry standard testing, refer to methods like the ASTM D3359 tape test.

You can find more detailed information about our equipment and services at IDS Equipment | UV Printers and Flame Treatment Systems and Contract Decorating Print Service.