UV Printing Frequently Asked Questions

UV printing is a digital printing process that uses ultraviolet (UV) light to instantly cure special inks as they’re printed. Instead of drying, the ink hardens on contact, creating sharp, durable, and vibrant prints. Because it cures instantly, UV printing works on almost any surface — plastics, glass, metal, wood, acrylic, and others — and supports both flat and curved items.

This technology is perfect for direct-to-object printing, making it ideal for short runs, customization, and fast production in signage, packaging, and promotional products.

👉 Learn more: What Is UV Printing and How Does It Work?

An inkjet printer creates images by spraying tiny droplets of ink onto a surface with extreme precision. It prints directly from digital files — no plates or screens required — making it fast, flexible, and easy to customize.

In industrial UV printing, inkjet printers use UV-curable inks that harden instantly under UV light, allowing direct printing on glass, metal, wood, and more.

Advanced Ricoh print heads (used in IDS printers) ensure accurate color, fine detail, and consistent results, even on curved surfaces.

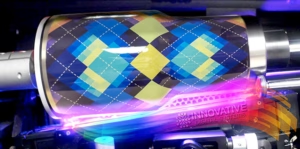

High-gap UV printing allows a UV printer to jet and cure ink from farther away than a traditional UV printer allows — ideal for curved or uneven surfaces like mugs, bottles, and industrial parts.

Traditional printers need a tight gap between the print head and surface. High-gap printers, however, use advanced print heads, UV inks, and powerful curing systems to maintain precision from a greater distance. The result: clean, durable prints on objects standard printers can’t handle.

👉 Learn more: High Gap UV Digital Printing: Revolutionizing Printing with Innovative Digital Systems

A UV printer is used to print full-color, high-resolution graphics directly onto all kinds of materials — plastic, glass, wood, metal, acrylic, and more. It’s ideal for direct-to-object printing on flat and curved items like mugs, tumblers, bottles, and packaging. UV inks cure instantly under UV light, creating tough, scratch-resistant prints that are ready right away.

You’ll find UV printers in industries from promotional products to industrial manufacturing for fast, customized decoration.

Direct-to-object printing means printing images or text right onto a product’s surface instead of using labels or transfers.

Using UV inkjet technology, it can decorate flat, curved, or textured items — from bottles and tumblers to metal panels or industrial parts. The UV ink cures instantly, so prints are vivid, durable, and ready for handling. DTO printing saves time, reduces steps, and gives products a polished, high-end look.

👉 Learn more: How UV Inkjet Printing Works for Direct-to-Object Applications

UV DTF printing stands for Ultraviolet Direct-to-Film and uses UV-curable inks to print vibrant, durable graphics onto a special film. The design is then transferred to hard surfaces using adhesive and pressure.

Unlike fabric DTF, UV DTF is made for glass, metal, wood, acrylic, and plastics. It’s perfect for irregular objects that are hard to print on directly — like bottles or textured products.

The cured prints are waterproof, scratch-resistant, and long-lasting. UV DTF is often used alongside direct-to-object printing for extra flexibility.

A UV printer can print on almost anything — plastic, glass, metal, wood, leather, acrylic, or ceramic. It’s used for everything from drinkware and phone cases to signs, packaging, and industrial parts.

With features like high-gap printing and rotary fixtures, UV printers can even handle curved or textured objects. That versatility makes UV printing perfect for customization, short runs, and on-demand decoration.

The easiest way to print on mugs is with a rotary UV printer, which holds and spins the mug while printing. Just load your design, mount the mug, adjust height and alignment, and print with UV-curable inks that cure instantly under UV light. The result? Full-color, wraparound graphics that are vivid, durable, and scratch-resistant.

IDS printers like the RevPro 360 and Prisma ZMax PRO make this process simple and precise.

To print on bottles, use a rotary UV printer with a cylindrical fixture that turns the bottle as it prints. After loading your design, mount and align the bottle, then print with UV-curable inks that harden instantly.

This process delivers seamless, high-resolution prints on glass, plastic, or metal bottles — waterproof, durable, and ready for production.

IDS printers like the RevPro 360 and Prisma ZMax PRO are built for precise, high-speed bottle printing.

To put a picture on a mug, use a UV rotary printer for direct-to-object printing.

Import your image, mount the mug on the rotary fixture, set the print height, and print with UV inks that cure instantly under UV light. You’ll get bright, photo-quality prints that are durable, waterproof, and scratch-resistant — no decals or heat transfers needed.

IDS printers like the RevHDL, RevPro 360, and Prisma ZMax PRO make printing photos or logos on mugs fast and easy.

A printhead is the part of an inkjet printer that sprays tiny droplets of ink onto a surface to form an image. It controls droplet size, placement, and speed — determining how sharp and consistent the print looks.

In UV printers, the printhead works with UV-LED curing systems that harden ink instantly. IDS printers use Ricoh Gen6 printheads, known for long-distance jetting, fine detail, and high precision.

A print bed is the platform that holds your item steady during printing. There are three main styles of print bed: flatbed, rotary or cylindrical, and conveyor.

Flatbed UV printers use a vacuum table for flat materials like acrylic or metal.

Rotary printers (also known as cylindrical printers) use a cylindrical fixture to rotate curved items, while conveyor-style printers use a moving belt for continuous, high-volume production.

Each setup keeps products stable and aligned for sharp, consistent results across different shapes and materials.

Related Insights from Innovative Digital Systems

How UV Inkjet Printing Works for Direct-to-Object Applications