Introduction

UV printing has revolutionized the commercial printing industry.

Whether you’re customizing drinkware, personalizing promotional items, or producing industrial-grade graphics on metal, glass, or wood — UV inkjet printing delivers a level of versatility and precision unmatched by traditional product decoration methods.

At Innovative Digital Systems (IDS), we’ve spent decades innovating and advancing this revolutionary technology — from bottles and tumblers to wooden plaques and phone cases — with stunning, durable imprints.

This guide explains what UV printing is, how it works, and what makes it so essential in today’s digital manufacturing landscape.

What Is UV Printing?

UV printing is a digital inkjet printing process that uses ultraviolet (UV) light to cure specially formulated inks directly onto the surface of an object. Unlike solvent or heat-based systems, UV printing relies on instant UV curing, meaning the ink dries the moment it’s exposed to UV light (through activation of photoinitiators within the ink).

This process allows printing on non-porous substrates and materials, such as:

That versatility makes UV printers ideal for DTO printing (direct-to-object), industrial labeling, and promotional printing applications.

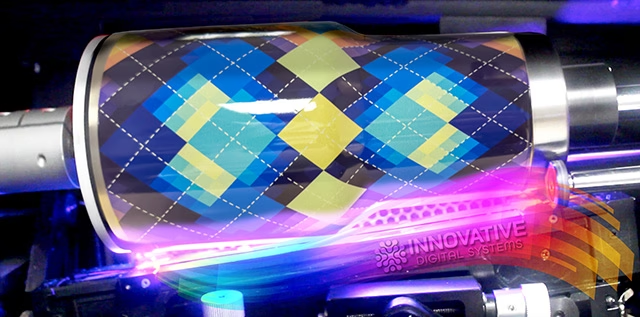

Modern UV printers — including rotary UV printers, UV printers with rotary attachments, and 360 rotary UV printers — can print on cylindrical, conical, curved, or contoured products like tumblers, bottles, and drinking glasses.

How UV Printing Works: Step-by-Step

Here’s how a UV printer produces high-quality, full-color prints on a variety of surfaces:

1. Digital Design Preparation

1. Digital Design Preparation

The process starts with a digital artwork file — often created in design software like Adobe Illustrator, CorelDRAW, SAI Flexi Design, or Affinity Designer. The design is loaded into the printer’s RIP (Raster Image Processor) software, which controls ink placement and color accuracy and includes specialized programs like FlexiPRINT, Onyx Rasterlink, or Caldera.

2. Object Placement

2. Object Placement

The object (glass, wood, bottle, or tumbler) is placed on the printer’s flatbed or rotary system and registered through the use of engineered fixtures and tooling. For cylindrical products, a UV printer rotary attachment or rotary UV printer tool rotates the object 360 degrees to ensure controlled printing.

3. Inkjet Printing

3. Inkjet Printing

The printer uses precision inkjet printheads to spray microdroplets of UV-curable ink directly onto the surface. IDS printers often use industrial grade Ricoh Gen4, Gen5, or Gen6 heads for maximum quality and durability.

4. UV Light Curing

4. UV Light Curing

Immediately after the ink is jetted, UV LED lamps cure (harden) the ink instantly. Paired with the proper pretreatments, this creates a bonded, durable image that can be scratch-resistant, chemical-resistant, and UV-stable — perfect for outdoor signs, drinkware, and decorative products.

5. Optional Treatments

5. Optional Treatments

For difficult low dyne materials like glass or metal, a flame treatment machine or UV adhesion promoter may be used before printing to improve ink adhesion. Inline jettable primers are available too.

Key Advantages of UV Printing

- Instant drying: No smudging or waiting times. Prints are immediately pack-ready.

- Multi-Purpose: Print on virtually anything from glass bottles to wood panels.

- Full-color, high-resolution results: With smooth gradients and photographic detail.

- Environmentally friendly: No solvents, harmful chemicals, or VOCs.

- Durable prints: Resistant to fading, moisture, and abrasion.

These benefits make UV printing a cornerstone for industries producing customized tumblers, glassware, wood plaques, metal signage, phone cases, and more.

Popular UV Printing Machines and Configurations

There are many types of UV printers, each tailored to a specific application:

1. Flatbed UV Printers

1. Flatbed UV Printers

Whether you are looking for a UV printer for wood, metal, or acrylic sheets, a flatbed UV or UV-LED printer is designed to handle flat objects that can fit neatly on the small format or wide format print bed.

2. Rotary & Cylindrical UV Printers

2. Rotary & Cylindrical UV Printers

Used for printing on curved surfaces like bottles, tumblers, or glasses. Models include the 360 rotary UV printer, Revolution 360T, the RevHDL, and other UV mug and bottle printing machines.

3. Single Pass UV Printers

3. Single Pass UV Printers

For high-speed industrial production where the object moves under a fixed printhead array. Used especially in promotional printing machines or packaging operations, such as the cap and enclosure market.

Applications of UV Printing

UV printing isn’t limited to one industry — it’s used across nearly every sector where customization or branding is needed.

Glass Printing

UV printers can print directly on drinking glasses, wine bottles, pint glasses, and glass cups with vibrant, durable results. IDS offers solutions like the glass printing machine, digital glass printer, and UV glass printer that handle everything from short-run promotional items to mass production. With use of Pyrosil you can achieve dishwasher durable print.

Bottle Printing

The UV bottle printing machine and bottle printer are essential for beverage branding and promotional packaging. Printing on stainless steel, plastic bottles, or water bottles is simple with the UV rotary printer or 360° rotary attachment.

Wood Printing

With UV flatbed printers like the Prisma or Mimaki, you can decorate wood plaques, awards, and signage with full-color imagery. UV printing on wood can produce a variety of beautiful, unique, and durable finishes perfect for décor and retail displays.

Metal & Plastic Printing

From printing on stainless steel to digital inkjet printing on plastic, UV technology excels far beyond traditional printers.

Use cases for the signage industry include plastic sign printers, metal sign printers, and UV printing on phone cases. Machines built for metal and plastic printing include the Prisma Z-Max Pro and the Sonic Jet.

High-Gap UV Printing Technology

High-Gap UV Printing Technology

Certain surfaces — such as curved tumblers, mugs, or irregular wooden items — require more distance between the printhead and the object being printed in order to maintain a clear and vibrant image. High-gap UV printing allows the printer to maintain excellent quality and crisp edges despite the greater jetting distance.

IDS Revolution 360T, Prisma Z-Max Pro, and other UV rotary printers support high-gap printing using industry-leading Ricoh print heads, enabling precise printing on unique shapes and textures without sacrificing detail.

Understanding Adhesion and Surface Prep

![]() Achieving long-lasting prints on non-porous materials often requires surface pretreatment:

Achieving long-lasting prints on non-porous materials often requires surface pretreatment:

- Flame treatment machines oxidize the surface to help ink adhere. This increases the surface energy and dyne level of a given substrate.

- UV adhesion promoters (primers) can be applied before printing to enhance bonding.

These steps are especially important for printing on glass, metal, or stainless steel.

Cost Considerations

UV printers vary widely in price, depending on capability and print area. Whether you’re looking for an entry level commercial printer or something for more volume, IDS has you covered. A few examples include:

● Mimaki UJF-7151 plusII e price: around $30,000–$40,000

● Revolution 360T printer price: depends on configuration (contact IDS for quoting) ● RevHDL printer price: varies by model and attachments

The ROI on UV printers is strong due to low consumable costs and high product value. Financing options are available for all IDS printer purchases.

Why Choose Innovative Digital Systems?

For over 30 years, Innovative Digital Systems has led the industry in direct-to-object UV printing technology. Our IDS printers — including our award-winning RevHDL, RevPro360, Prisma Z-Max Pro, and others — combine industrial reliability with unmatched print quality.

IDS provides:

- Expert support and training from our tech service team

- Advanced printer configurations (rotary, high-gap, single pass)

- Customized integration for high-volume workflows

- Industry leading engineering

We’re not just selling printers — we’re offering innovative digital solutions and helping commercial printing businesses succeed by producing higher quality prints, faster and more efficiently than ever before.