An expert guide on UV inkjet printing

UV inkjet technology has revolutionized how companies decorate products. With today’s technology, you can print full-color, vibrant graphics directly onto a wide array of consumer goods, such as bottles, tumblers, glassware, wood, and more—without the use of labels, heat transfers, or screens. The result? Fast, durable, and professional multi-color decoration for just about any shape or material.

1. What Makes UV Inkjet Printing Different

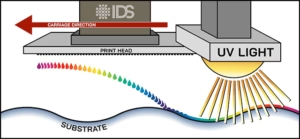

Unlike other traditional printers and alternative analog print methods that rely on evaporation or heat to dry ink, UV printers instantly cure ink using UV light. The printhead jets tiny droplets of ink directly onto the product surface, and a UV-LED lamp follows immediately behind to harden the ink on contact.

Because the ink cures instantly, there’s no smudging, waiting, or drying time, which makes UV technology ideal for printing on rigid and nonporous materials like glass, wood, metal, and plastic.

This process also opens up huge creative potential—printing directly on curved, contoured, textured, or irregular products that traditional printing methods can’t handle.

2. How Direct-to-Object UV Printing Works

Here’s how most UV printers, rotary UV printers, UV bottle printing machines, and tumbler printers operate:

- Design Setup – Your artwork is prepared digitally in digital design software, typically using CMYK plus optional white and clear (varnish) layers for producing texture, matte, tactile, raised, or gloss effects.

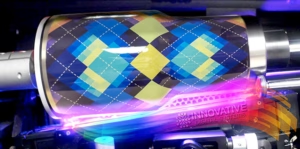

Inkjet Application – The UV printer jets UV-curable ink directly onto the object surface. For cylindrical items like bottles or tumblers, the fixture rotates the object while the gantry moves laterally—ensuring precise, 360-degree coverage.

Inkjet Application – The UV printer jets UV-curable ink directly onto the object surface. For cylindrical items like bottles or tumblers, the fixture rotates the object while the gantry moves laterally—ensuring precise, 360-degree coverage.- Instant Curing – UV-LED lamps cure the ink as soon as it’s applied. This solidifies the image immediately and bonds it to the surface.

- Ready-to-Use Finish – Because curing happens instantly, products come off the printer completely dry and ready for handling or packaging.

This gives you greater efficiency, consistency, and output quality.

3. The Machines Behind the Process

-

Rotary UV Printers

Rotary or cylindrical printers are built for cylindrical, conical, or curved products like bottles, tumblers, and mugs and include machines like our Revolution 360T, TwinRev 360, QuadRev 360, and the RevHDL. The item is placed in a specially designed fixture, which rotates or oscillates the object during printing to achieve seamless 360-degree coverage with vibrant, durable UV inks.

Rotary or cylindrical printers are built for cylindrical, conical, or curved products like bottles, tumblers, and mugs and include machines like our Revolution 360T, TwinRev 360, QuadRev 360, and the RevHDL. The item is placed in a specially designed fixture, which rotates or oscillates the object during printing to achieve seamless 360-degree coverage with vibrant, durable UV inks. -

Flatbed UV Printers

Flatbed or scanning UV printers provide exceptional flexibility for both flat, large, or irregularly shaped items. This includes machines like the Prisma Z-Max Pro. These flatbed UV printers can handle signage, panels, and promotional products quickly and easily.

-

Single-Pass Printers

Single-pass printers use stationary printheads that cover the full width of the material, printing the entire image in one continuous motion as the object passes underneath. This design eliminates back-and-forth scanning, delivering faster speeds, sharper detail, and consistent color—ideal for high-volume production in packaging, labeling, and product decoration.

Single-pass printers use stationary printheads that cover the full width of the material, printing the entire image in one continuous motion as the object passes underneath. This design eliminates back-and-forth scanning, delivering faster speeds, sharper detail, and consistent color—ideal for high-volume production in packaging, labeling, and product decoration.

-

Surface Treatment Equipment

For the best adhesion and print quality, flame treatment machines and auxiliary pretreatment systems like the PyroBond 4GL and PyroTrack are used to prep glass, stainless steel, and powder-coated surfaces. These support tools ensure consistent results and long-lasting durability.

For the best adhesion and print quality, flame treatment machines and auxiliary pretreatment systems like the PyroBond 4GL and PyroTrack are used to prep glass, stainless steel, and powder-coated surfaces. These support tools ensure consistent results and long-lasting durability.

4. Why UV Inkjet Printing Works So Well

The appeal of UV printing goes beyond convenience—it’s about performance and versatility:

- Instant Results: Because UV ink cures on contact, there’s no waiting or drying. Parts can be printed, packed, and shipped immediately.

- Broad Material Compatibility: UV ink adheres to glass, wood, metal, plastic, leather, and coated substrates often without special treatment—though a flame treatment machine or jettable primer can enhance adhesion on some hard-to-print surfaces and substrates.

- Vibrant, Durable Graphics: The cured ink forms a tough, scratch-resistant layer that resists fading, moisture, and abrasion – and can be dishwasher durable.

- Efficient, Eco-Friendly Process: UV curing uses less energy and produces minimal waste compared to solvent or heat-based printing methods.

- No Labels Required: Print directly on the product—no film, adhesives, or additional application steps—making it ideal for promotional printing, custom gifts, or branded packaging.

Speed, durability, and versatility are what make UV printer applications so popular across industries, from consumer products to industrial marking.

5. Where You’ll Find UV Printers in Action

Because UV inkjet systems can print on almost anything, they’ve become essential tools for decorators, manufacturers, and creative professionals. Common applications include:

- Drinkware Printing: UV printers for tumblers, pint glass printers, drinking glass printing machines, and water bottle printers create full-color designs on curved surfaces.

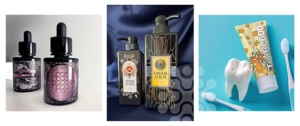

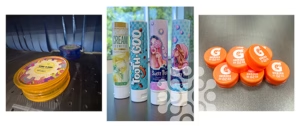

- Packaging & Branding: Bottle UV printing and digital bottle printing machines produce sharp, consistent branding for beverages and cosmetics.

- Signage & Décor: Printers for wood, metal sign printers, and plastic sign printers deliver custom graphics for plaques, awards, and displays.

- Electronics & Accessories: UV printers for phone cases and small promotional items print directly onto plastics, silicone, and coated metals.

- Industrial & Specialty Markets: UV printing on stainless steel, UV printing on plastic, and UV printing on glass are increasingly used for durable product labeling and customization.

Whether you’re printing a short run of personalized tumblers or mass-producing branded bottles, UV inkjet technology combines flexibility with professional-grade quality.

6. The Future of Direct-to-Object Printing

As UV technology advances, machines are becoming faster, smarter, and more dynamic. From small batch runs to large scale productions with thousands of bottles being printed per day, the capabilities of UV printing continue to evolve and grow with the industry – redefining what’s possible in product decoration.

With improvements in ink chemistry, adhesion, and curing systems, UV printing will remain one of the most efficient and sustainable ways to decorate three-dimensional products—offering unmatched speed, color, and creativity for businesses and end users worldwide.

With improvements in ink chemistry, adhesion, and curing systems, UV printing will remain one of the most efficient and sustainable ways to decorate three-dimensional products—offering unmatched speed, color, and creativity for businesses and end users worldwide.

7. The IDS Advantage

Innovative Digital Systems (IDS) has been at the forefront as pioneers of this groundbreaking technology, developing UV printers and innovative digital solutions that make product decoration easier than ever.

IDS digital printing solutions include flatbed, rotary, and single pass UV printers for glass, wood, plastic, and metal applications. As one of the most innovative digital print equipment providers in the market, IDS helps businesses adopt reliable, scalable technology to expand their promotional and industrial printing capabilities.